Our Business

Lakshmi shell LLP is the noted Manufacturer & Supplier of Resin Coated Sand in the domestic market. We are producing industry standard quality of foundry products for its Indian metal casting industry and automobile industry. We offer it in high-grade packaging materials to ensure zero contamination during transit. Also, we ensure timely delivery of the orders. We hold expertise in handling the bulk orders with the acute sense of responsibility. Customer Satisfaction: We always strive hard in order to achieve 100% customer satisfaction and thus we conduct different tests to ensure flawless range of products. Over the course of its journey the management had manifold in the industry. The belief that customer satisfaction is as important as our product and services have helped us garner a vast base of customers, which continues to grow day by day. Our employees are dedicated towards their respective roles and put in a lot of effort to achieve the common vision and goals of the company. We are expecting to expand our line of products in the near future.

Facility

Machinery and Equipments

Services

Resin Coated Sand

Used for producing a casting of highly precise dimensions, smooth surface, free of blowholes & to avoid casting defects. All grades of resin coated sand for the preparation of shell cores and moulds either by conventional dump box method or by core shooter. Specially formulated to reduce emissions, smoke, and odor during the production of cores and moulds in ferrous and non-ferrous metal casting. Superior blending capabilities and quality control procedures allowing us to deliver sand within a very tight and consistent range on each required sieve screen.

- We are able to produce critical specification like low resin coated sand.

- We are capable for produce 3000 MT/Month resin coated sand

- Handling used resin coated sand in government approved way

- Generate the same quality and specification during rainy season

- 50 kgs Hdpe bags.1 Ton Jumbo Bags.

- All AFS Silica Sand as per customer requirement

- Keep the customer environment green and clean

- Delivery to customer site as per needs on time

Thermal Reclaimed Resin Coated Sand

We take back used core sand from customers and have two dedicated Reclamation plant in two different sites to thermal reclaim the sand back to silica sand and then produce the resin coated sands. The benefits are reduced resin usage and greater enviromental benefits

- Tailor made Resin Coated Sand as per customer specifications & requirements

- Part of go green initiative and able to recycle the used core sand

- Recycle the waste sand in government approved way

- Generate the same quality and specification during rainy season

- 50 kgs Hdpe bags.1 Ton Jumbo Bags.

- All AFS Silica Sand as per customer requirement

- Keep the customer environment green and clean

- Delivery to customer site as per needs

Thermal Reclaimed Silica sand

We have trusted name as Supplier of Thermal Reclaimed Silica sand. We are able to bring forth the best quality of Silica sand, which has the high percentage of silica and low clay content. We assure buyers that the Dry Silica sand what we produce has no impurities. Our quality team ensures the best quality silica sand and Low Hazardous Air Pollutant (HAP) products. Silica sand is widely used in many purposes according to its high purity of Silicon content and low Iron content. Our Silica sand is used in Glass Industry, Crystal Industry, Silicon Metal, Silica Sand For Glass, Foundry, Painting, Oil And Gas Stamped Concrete, Water Filtration, Pool Filter, Golf Course, Water Treatment, Plastering, Ceramics And Glaze Frets. This sand needs less resin as well since it is thermal reclaimed and has greater environmental benefits

- Tailor made Silica Sand as per customer specifications & requirements

- Sieving as per customer requirement (AFS)

- High silica content

- Low clay content

- Low resin addition

- Silica content Min 98.5 %

- Clay Content NIL & Dried by fluidized bed drier

- We can able to produce the customer’s critical specification also.

- All AFS Silica Sand as per client requirement

- 100 % Possible to reduce the resin addition to our sand

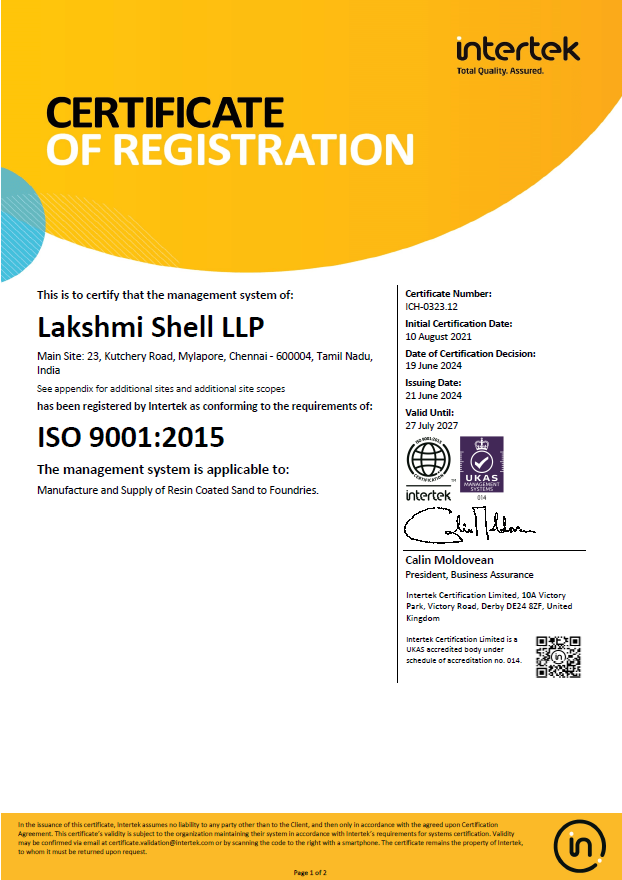

QUALITY

AFS Testing

Foundry sand testing is a process used to determine if the foundry sand has the correct ... Fineness number (grain size/AFS Number) of the base sand.

The sand washer assembly consists of a motor stirrer unit, glass wash beaker, cleaning brush, metal stand, siphon tube and control box. An extra beaker is provided to enable the second test to be carried out concurrently within the settling and drying periods of the first test. The metal stand is designed to accommodate the wash beaker during the agitation period of the test and the siphon tube allows the clay/water suspension to be siphoned off, after the settling periods, without disturbing the sand grains in the beaker. The control box provides an essential means of timing and controlling the agitation and settling periods. It incorporates an alarm buzzer as well as a facility for by-passing the timer and allowing the stirrer to run continuously.

HTS Testing

HTS Testing is done each lot to find out the strength of the core as per the specification.

The potential for hydrogen in substances is measured by the pH scale, which runs from 0 to 14. Seven on the scale is neutral. A pH that is 0 to 7 is considered more acidic, with 0 being a high level of acidity. A pH in the range of 7 to 14 is basic, or alkaline, with 14 being at the highest basic level. Pure sand is mostly made from silica, a substance with a neutral pH of 7. But pure silica is rarely found outside laboratory settings. Sand in your garden or for sale in garden centers will have other materials mixed in. These can include living organisms, vegetative matter, even water, and salts. All these things affect the pH of what is recognized as sand.

Stick Point Testing

Stick Point Testing is also carried out as per the specification

Mechanism:

Clay Washing along with automized cycle, microcontroller based electronic control box.Misc Spec.:

Auto Clay washer conducts clay washing cycles automatically. The Number of cycles and washing time can be set by the user. It eliminates The need of Siphoning out water manually and other major manual interventions such as time punctuality for siphoning etc, ensuring The accuracy of readings.Sand Type:

Silca Sand,Application:

To check Total clay contents of sand sampleOUR CLIENTS

The Resin coated Sand, offered by us, is as per the exact specification requested by clients. Repeated orders from various clients are the testimony of our excellent quality, quantity and on time delivery. Our Resin coated and Thermal Reclaimed Sand is thoroughly tested in our well facilitated Lakshmi shell Testing Lab so that the customers always get the best quality. Such features have brought a name among the prominent natural Resin coated sand Suppliers operating from India. Our valuable clients are from leading foundries manufacturing automobile castings, Pump and Motor Casting and general Engineering castings.

What Our Client Says

Our Customers are always happy and the cores done by our Resin coated Sand are of superior quality giving us more business. Also we keep adding customers and our customers always have a long term business engagements with us.